GIANT BULL ANIMATRONIC BIRMINGHAM

COMMON WEALTH 2022 OPENING CEREMONY

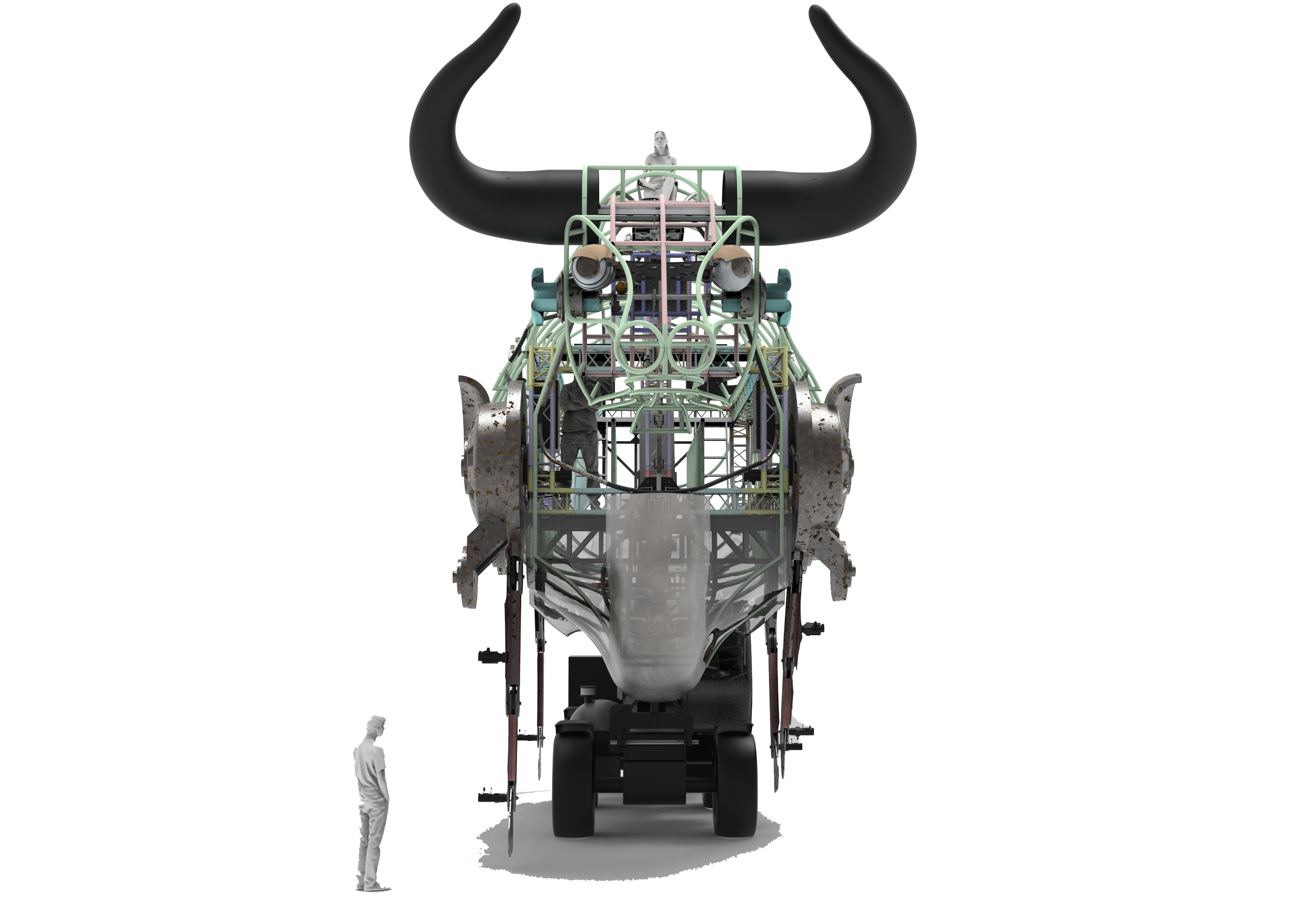

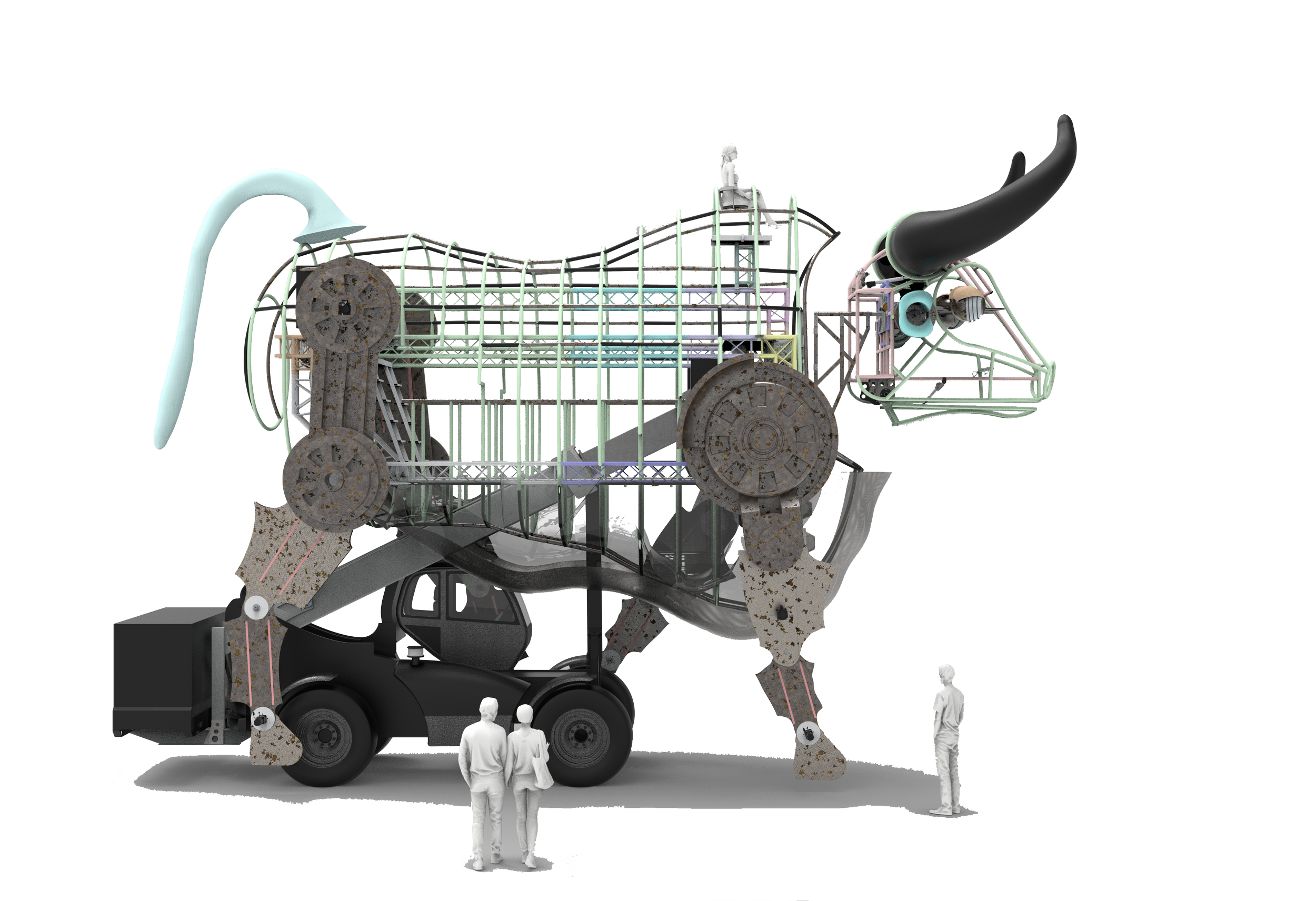

Voilá! The 8m high Giant Bull Animatronics used for the opening ceremony of the Birmingham Commonwealth games 2022.

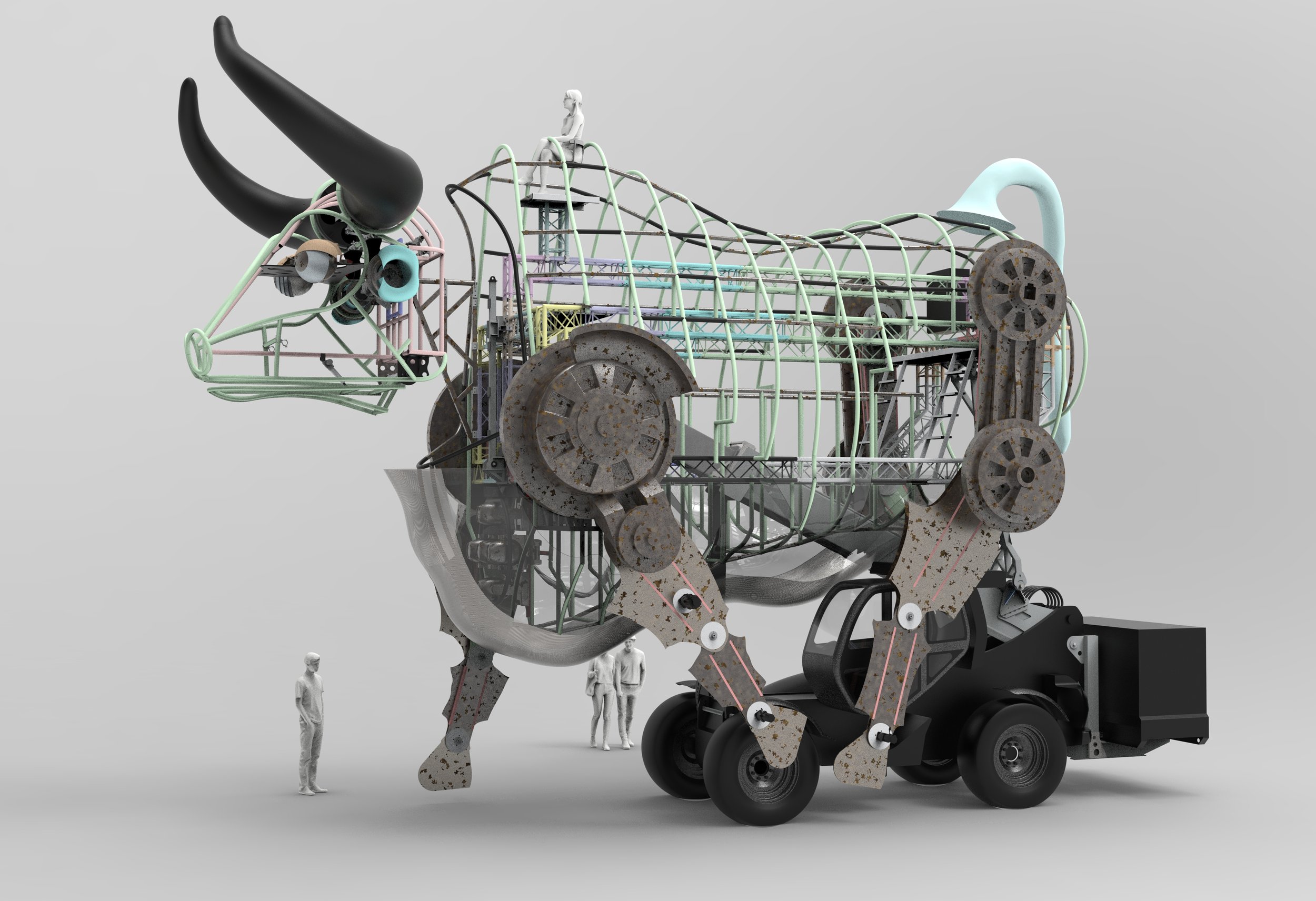

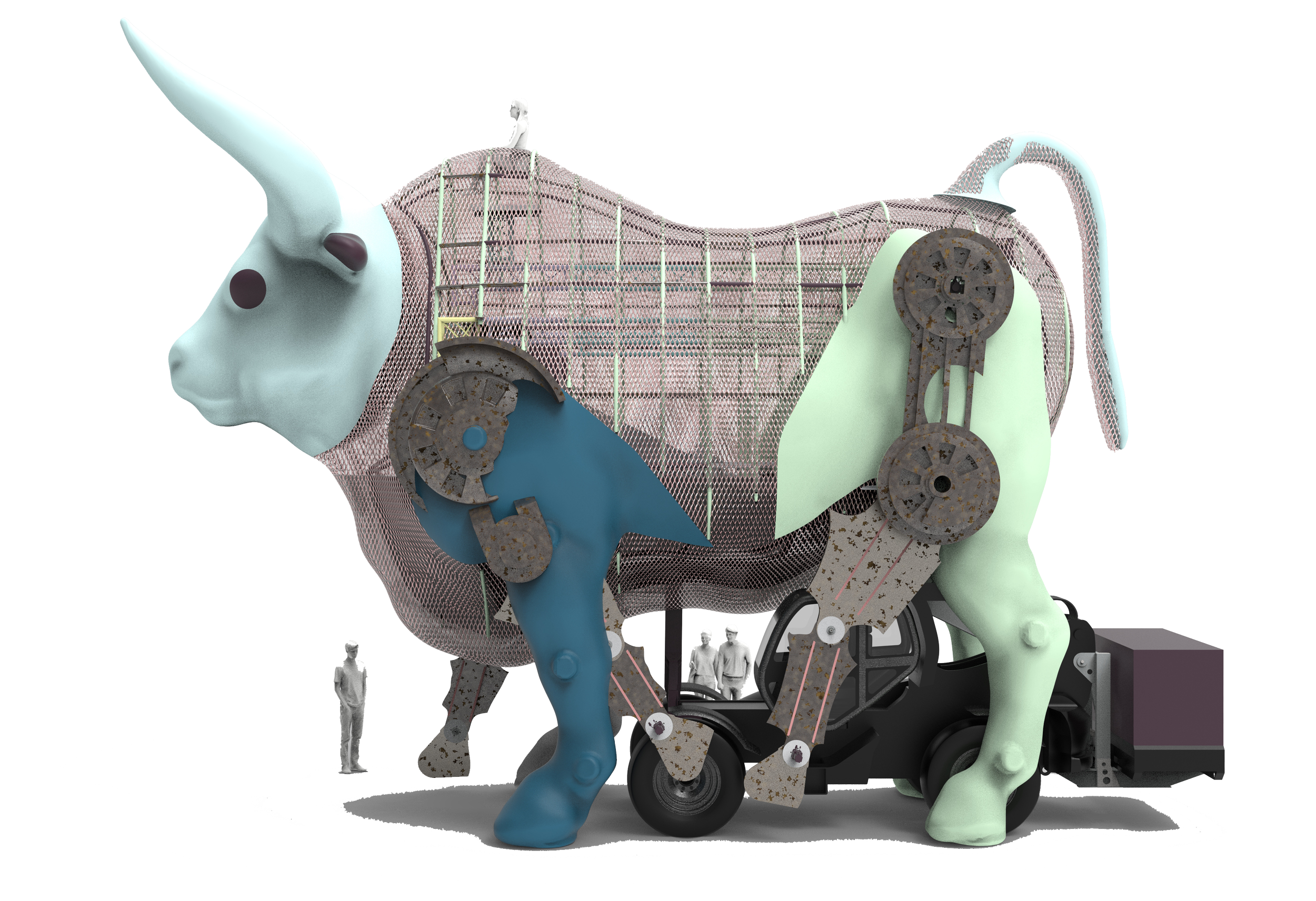

A 8mHx12mLx5mW Steampunk animated robot referencing the industrial revolution as well as the bull fights occuring in the city in the 16th Century.

I had the pleasure to research, shape, develop and design some parts of the project working internally for Artem-Special Effects from the first steps of discussions with the Art Director and the head of the Commonwealth games.

Reviewing the anatomy of the beast was the first step as well as exploring the design and setting the proposal to win the job.

Of course a lot of research in animatronics, giant robots and puppeteering at this stage was essential.

From when the job was secured, the complete sequence of methodology included:

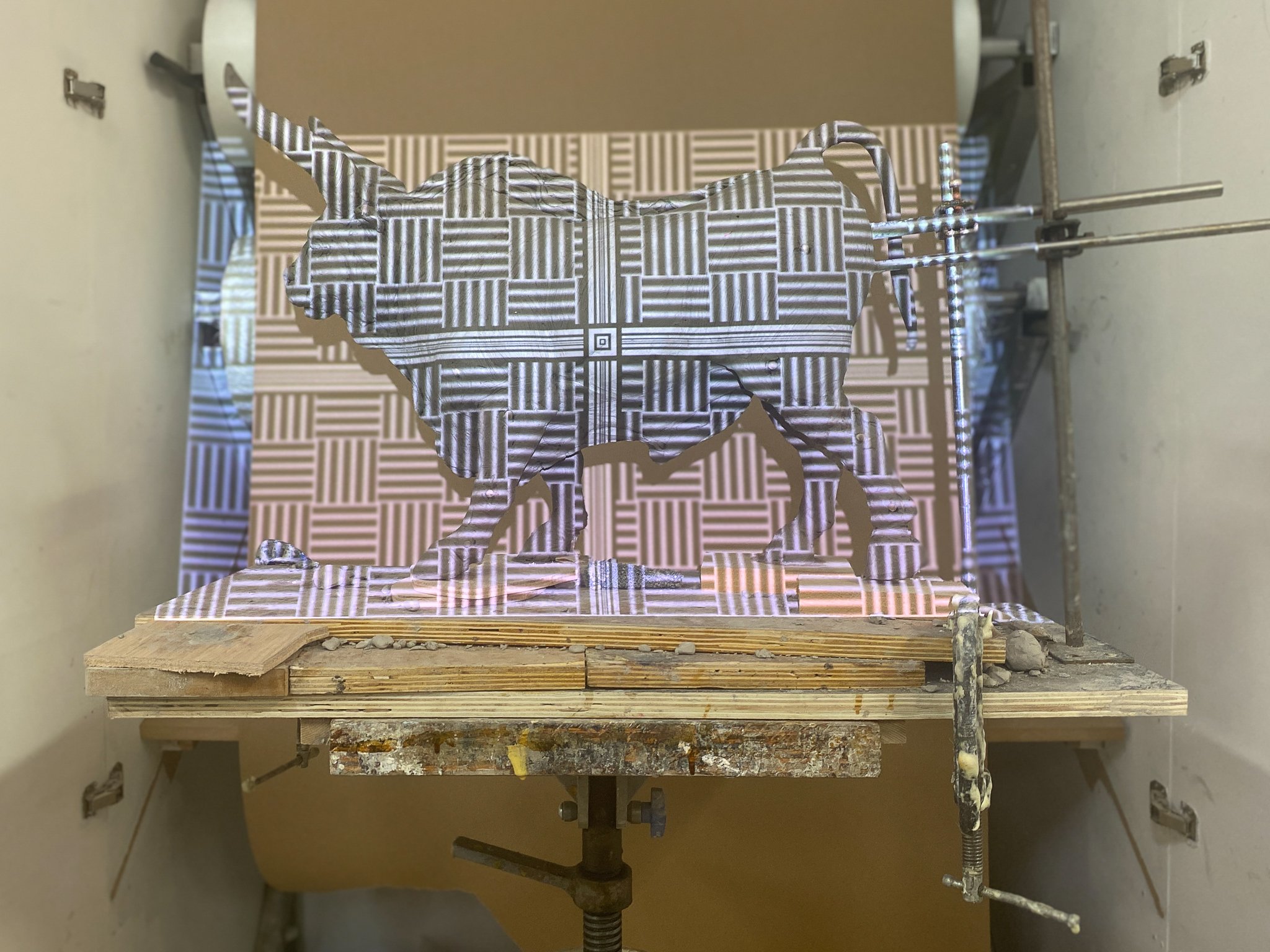

1/ Physical Clay Sculpting

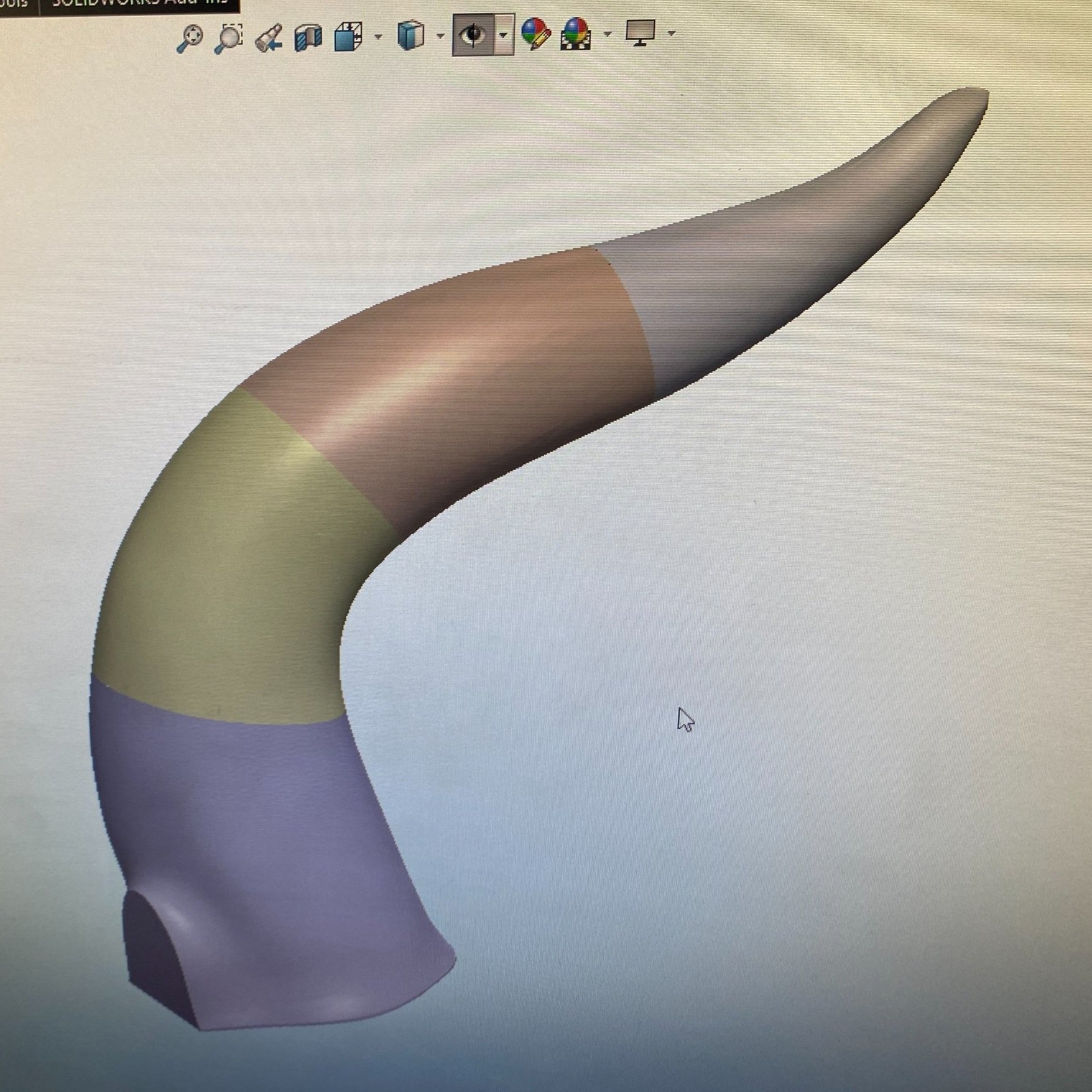

2/ 3D Scanning

3/ 3D Digital sculpting using Geomagic Freeform & its haptic device (3D pen)

4/ Import into CAD using Solidworks

5/ Defining the Skeleton

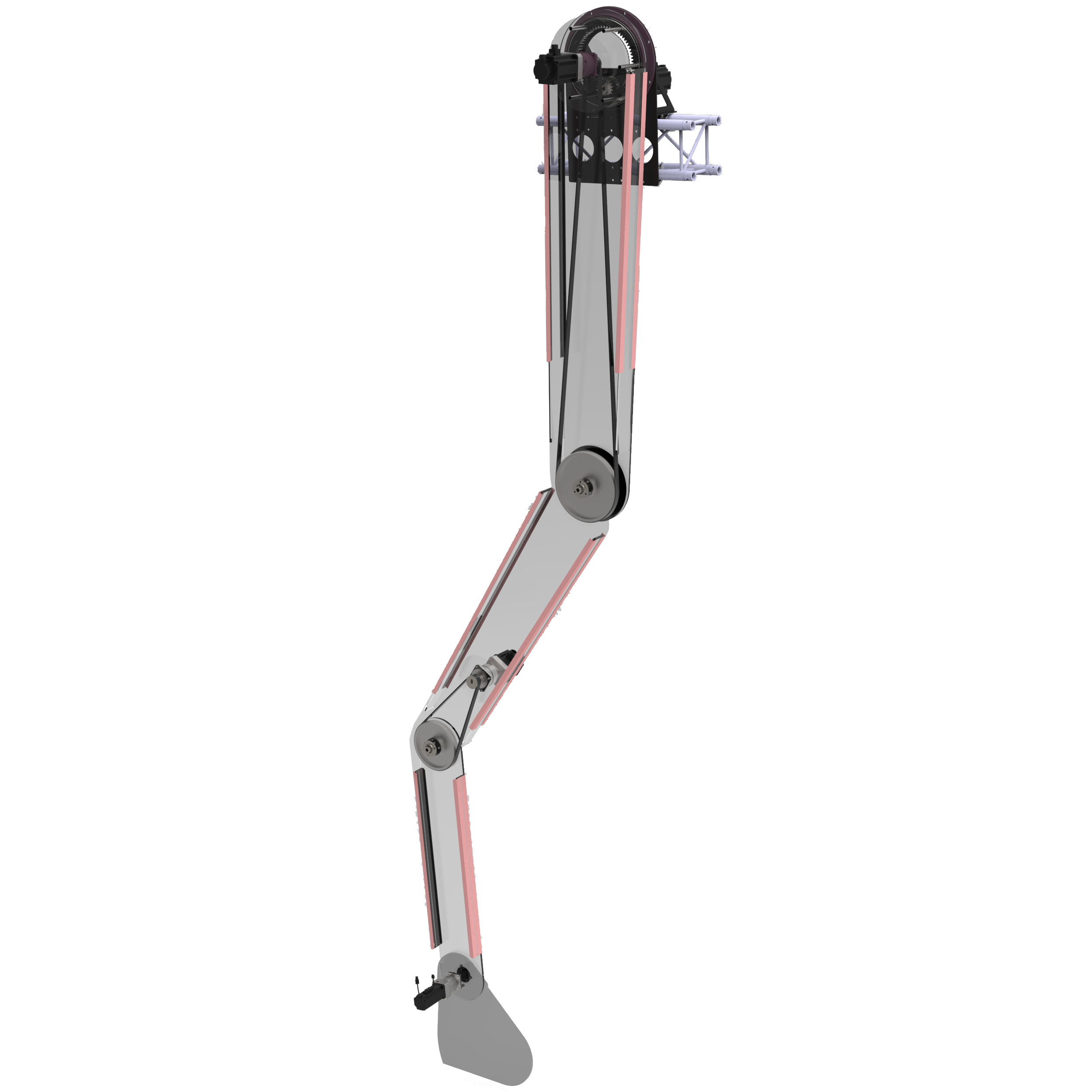

6/ Design of the core structure and legs

7/ Decision of the legs motion actuation.

8/ Slicing up the model to take references for the outer shape structure.

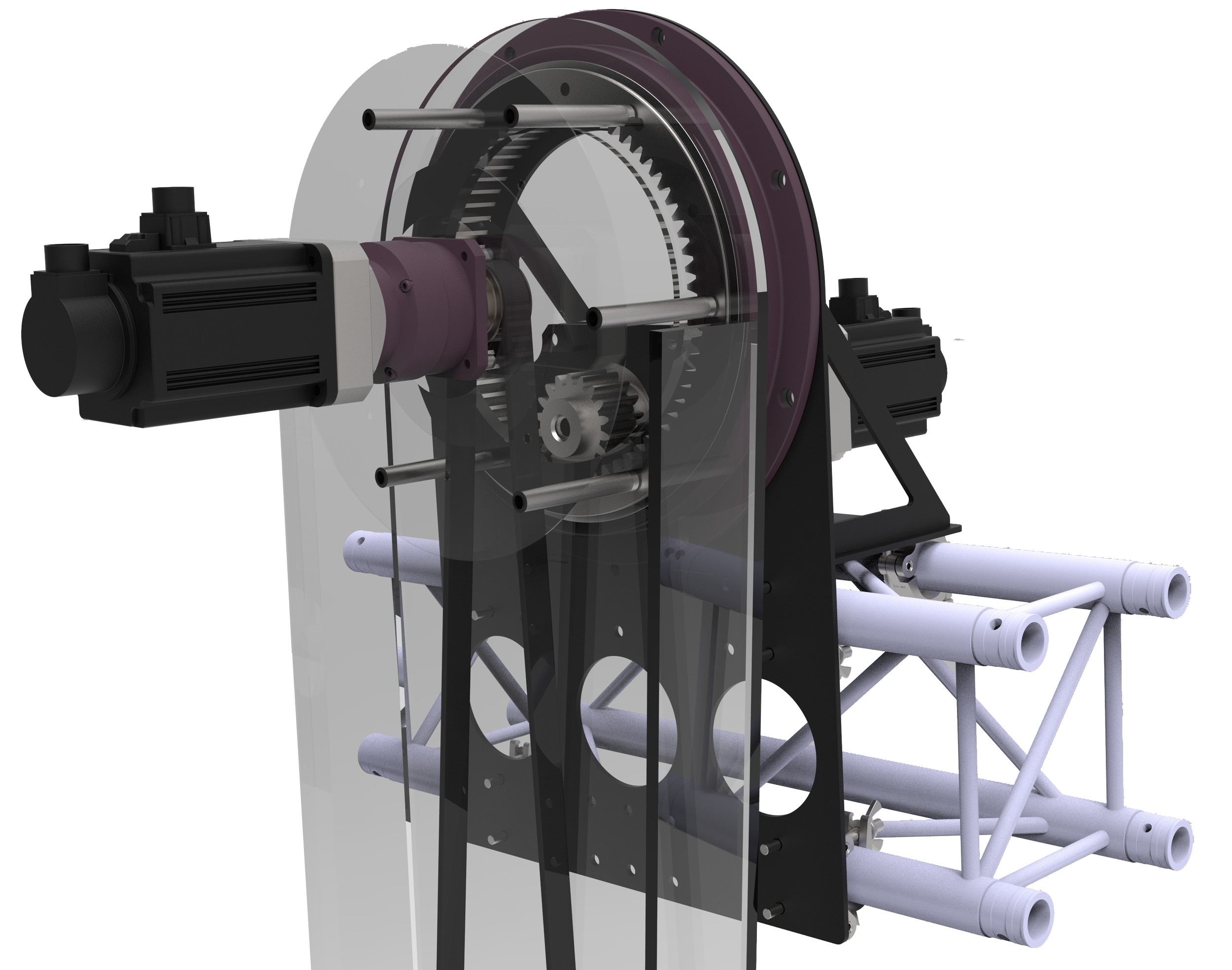

As we decided to use an electrical actuation with gearbox servo motors, the selection and sourcing due to the important torques (1705Nm @ the hips axis) was a critical phase as per the material availability on the market & deadline to get the robot ready.

Developing such torque obviously implied using torque multiplier such as Slewing Ring (Hips) and Belts and Pulleys for the rest of the joints.

More actuations of the head features were either remotely controled with servos & linear actuators as well as human puppeteering.

Another main challenge concerned the sourcing of a telehandler that could cope with the load of the robot + pupetteers + extra devices for the lights, smoke and sounds effects. With the boom extending at arequired stroke and at the adequate angle so it could reach the moutning points and still support the weight without tipping.

In order to optimise the weight the Inner structure was made with ali trusses, the legs formerly achieved with ali Honeycomb panels; most of the outter shape features were either achieved with Grp moulded parts and Plastazote polyethylene foam.

I had the pleasure of using a versatile bunch of machines & tools to achieve the various componets by using 3D scanning, a CNC Kuka robot 7 axis, a CNC router 3 axis, 3D printers, Plasma Jet Cutting as well as all the traditional tooling such as Lathe, Mill and various Jigs.

Standing

POSITIONS PRESETS STUDY

Charging

Jumping

Kneeling

METHODOLOGY / WORK IN PROGRESS